Jarvik Heart, Inc

Ventricular Assist Devices

September 2016 - March 2018

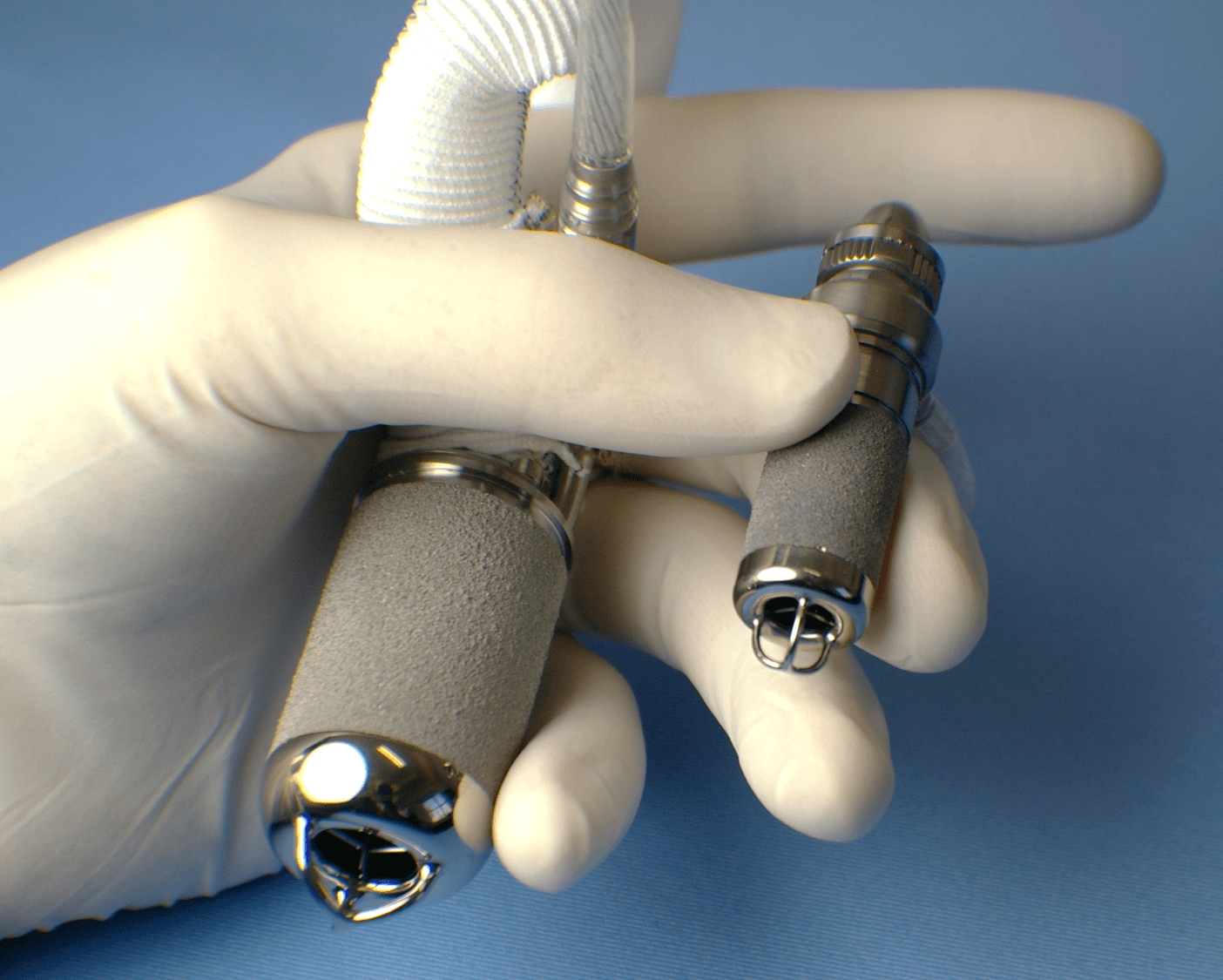

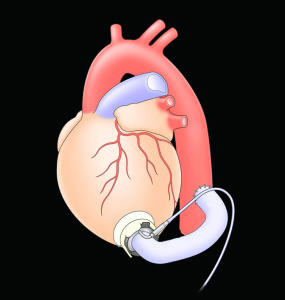

After my year at Disney ended, I returned to New York City and began working in my current position as a mechanical engineer at Jarvik Heart, Inc. (JHI). Jarvik Heart was founded by Dr. Robert Jarvik, the inventor of the first permanent total artificial heart, who runs the company as CEO. JHI currently produces two models of Ventrical Assist Devices (VADs): the Jarvik 2000, and the new, smaller Jarvik 2015, which is a part of the NIH PumpKIN Trial.

As a mechanical engineer, I am involved in the continuous improvement of our manufacturing processes. I have specialized in the production of the cabled housing sub-assembly, which includes the main cylinder of the VAD that houses the electromagnetic motor stator, all the way down the driveline cable to the connector that delivers the VAD power from the battery.

During my time at JHI, I have implemented engineering improvements that reduce production time and increase yield, making the VAD assembly process easier for technicians and more efficient to produce. I have gained hands-on experience building and testing FDA Class III medical devices, which has been an education in precision engineering, with many part tolerances in the tens-thousandths of inches range. Finally, I have grown familiar with standard practices in the medical device industry, such as process validation and equipment qualification, as well as the regulatory standards of ISO, FDA, PMDA (Japan), and CE Marking (Europe).

Creating VADs has also been a rewarding experience on a personal level, as I was born with congenital heart disease and have undergone two open heart surgeries in my life thus far. When I underwent my second surgery at age 20, a pulmonary valve replacement, I vowed to dedicate my life toward two goals. One was to pursue my earliest childhood dream of designing theme park technology, such as roller coasters and animatronic robots (this lead to me working at Walt Disney World 5 years later). The other was to design medical technology that would help others such as myself with serious medical conditions. Every VAD that I help make is special, because I know what it is like to owe my life to technology produced by science and engineering. Wherever my career takes me, I am guided by this principle of using engineering to create a positive and meaningful impact.

Images from jarvikheart.com