Precision Lathe Design

2.720: Elements of Mechanical Design

Spring 2023

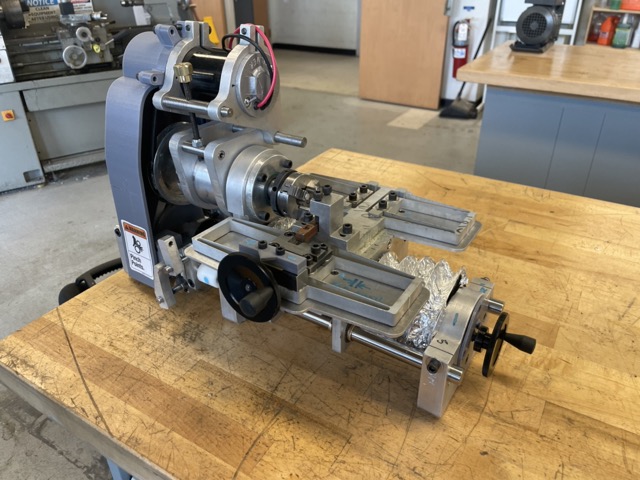

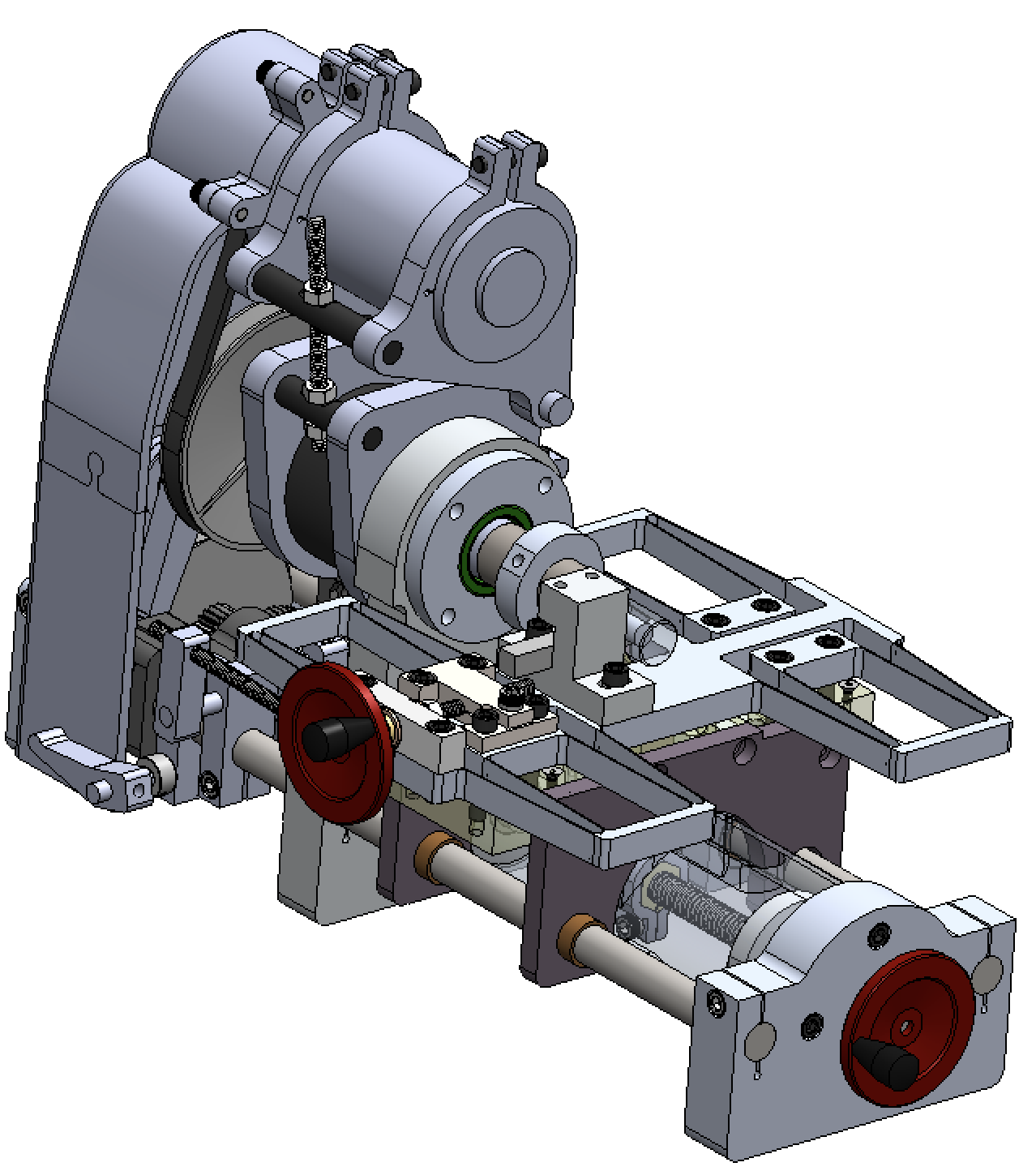

2.720 was both the most intense and most rewarding class that I took at MIT. The class teaches the principles of precision mechanical design through the creation of a desktop lathe with sub-50 micrometer precision after withstanding a drop from a desktop. I learned how to model the mechanics of specific machine elements, including bearings, bolts, belts, and flexures. I also learned general best practices for mechanical design: starting from clear and specific functional requirements, making “yes-no-maybe” decisions for the level of analysis needed, precision machining using mill, lathe, and waterjet machines, and measurement and testing of what we built to ensure our functional requirements were met.

On my team, I was the Computer Aided Design and Budget/Scheduling guru. This means I was responsible for the administration of all 3D SolidWorks models and 2D engineering drawings in addition to taking responsibility for keeping our team on a tight budget and a tighter timeline. I have worked on engineering teams in industry to meet demanding requirements and timelines; the 2.720 lathe project was just as challenging. In the end, my team came in 1st place by turning the most parts to the specification within the time limit.